Acumatica Manufacturing Edition – Planning with Acumatica Production Scheduling Software

The new 2017 R2 Acumatica Cloud ERP Manufacturing Edition is key to enabling manufacturers to manage the order-to-production-to-cash process. It all starts with telling the system what to produce and when. There are two ways to do that and this article covers how to create a Master Production Schedule (MPS) – a plan of the end items to produce for sale. A previous article entitled “Acumatica Production Scheduling Software – Creating a Forecast” covers how to use the Generate Forecast screen to create a sales forecast the Manufacturing Edition.

In this blog, we will explore the Acumatica Production Scheduling Software – Manufacturing Production Schedule solution. First, we wanted to share our free whitepaper. We have the Acumatica Cloud ERP Manufacturing implementation process down to a science based on field-tested and proven methodologies to help you with a plan specific for your business.

This whitepaper will help you get prepared for a successful cloud ERP implementation. These questions have been developed by our ERP consultants who are industry experts in helping small to medium-sized businesses overcome challenges with technology.

Acumatica Production Scheduling Software – Master Production Schedule

The Acumatica Manufacturing Edition enables users to enter a plan of which end items to produce in anticipation of future sales. That production plan is then used by the Acumatica production scheduling software to suggest the creation of Production Orders for subassemblies and final assemblies. The system also generates action messages to buy components at the right time to meet the production plan.

Master Production Schedule Creation Steps:

- Prior to loading an MPS, calculate which end items you plan to produce and when during your planning horizon. A planning horizon is the cumulative lead times for raw material acquisition and assembly of products and is used in anticipation of customer demand. As discussed in the post on Generate Forecasts make sure the management team agrees with the planned production levels and in particular sales, production and finance team members.

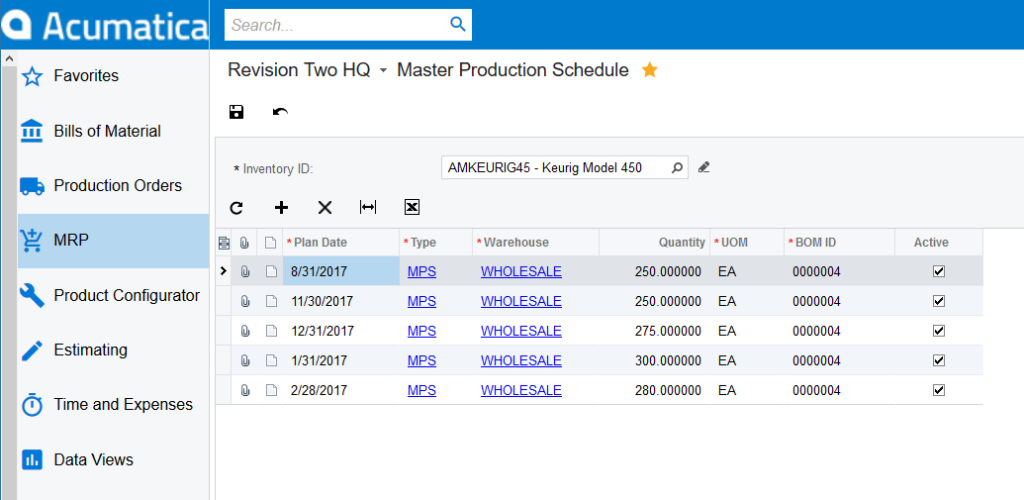

- The MPS is loaded by item in the Master Production Schedule screen, once you have determined the schedule. It can be loaded manually or via data import.

- One approach to determining the MPS levels for all end items would be to start with the Generate Forecast screen to calculate a forecast for your planning horizon based on historical sales. Then use the Export to Excel option and make any modifications to the schedule in Excel including adding the BOM ID for each item.

- Then create an Import Scenario and load the records into the Master Production Schedule screen as shown above.

Creating a master production schedule or sales forecast is the first step in taking full advantage of the production scheduling software features in the new Acumatica Manufacturing Edition. We will cover more steps in the process in future posts.

To learn more:

Download this FREE whitepaper: “Top 10 Questions to Ask to Avoid Cloud ERP Implementation Mistakes”

Stratotech Partners, LLC. – Acumatica Production Scheduling and Cloud Manufacturing Consultants

Headquartered in Seattle, Washington, Stratotech serves Acumatica customers in the Seattle metropolitan area and northwest region. Stratotech’s expertise allows them to focus on small to mid-sized manufacturing companies who are outgrowing existing systems and looking for lower cost cloud-based alternatives. Stratotech is a certified Acumatica cloud ERP and Smartsheet provider. These are leading cloud platforms for collaboration and project management.

Stratotech Partners, LLC is an Acumatica Value Added Reseller (VAR) partner. Our experienced consultants provide cloud-based business management software to enable small and mid-sized companies to accelerate their businesses. Acumatica is built on modern cloud and mobile technology and has a unique customer-centric licensing model. Our specialties include business management applications such as Financials, Distribution, CRM, and Project Accounting, on a robust and flexible platform.

For more information, please visit our website, call 206-336-9197 or email us.

Follow us on: